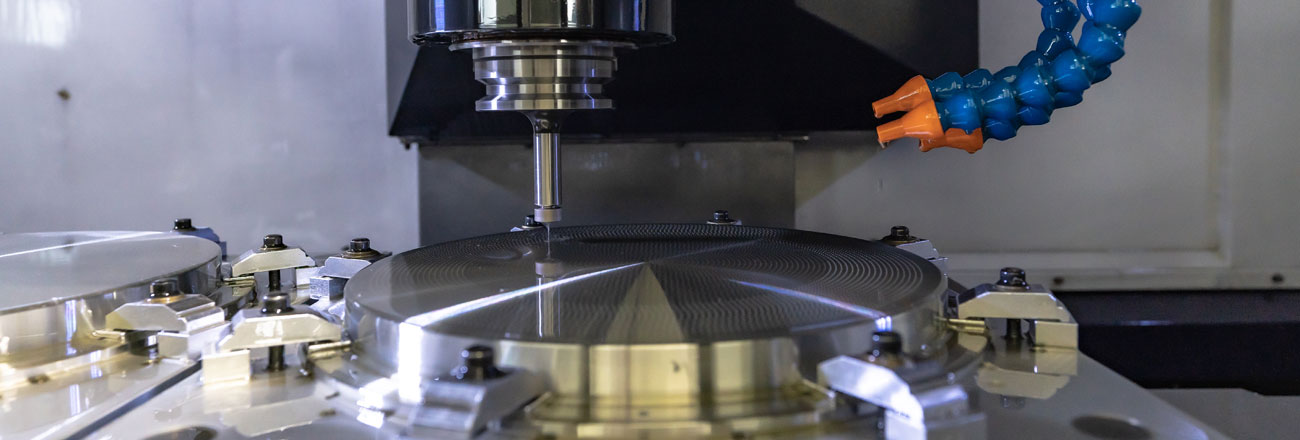

Hole processing

We has the greatest competitiveness in processing fine holes of aluminum. We can process holes up to ø0.3, and can process as many as holes and a pattern at a customer's request. We satisfy ±0.05mm of tolerance in processing numerous fine holes and can make a tolerance deviation even. In addition, since we have the differentiated technology to make the internal surface of a hole even, we can meet a customer's criterion. With our hole processing competency, we can spray gas evenly and accurately to Shower Head so as to improve the quality and yield of semiconductor products.

Precise size

We makes its most effort for more fine processing beyond a customer's criterion. Currently, the largest processing size is ø485, and we can process a hole within ±0.01mm of tolerance, and we can verify by 3D mesurement system. In addition, we manages a size within ±0.03mm of plane figure in the processing process in consideration of transformation at the time of welding. For precise processing, we divide and manage all processes in detail.

Processing tool

To secure excellent processing quality, We aggressively invest, and make greater effort in tools and cutting oil. To optimize product processing, we use the best tools. In particular, our drills are specially made by global famous brand company. By managing tools thoroughly, we do the best to provide the best quality constantly.

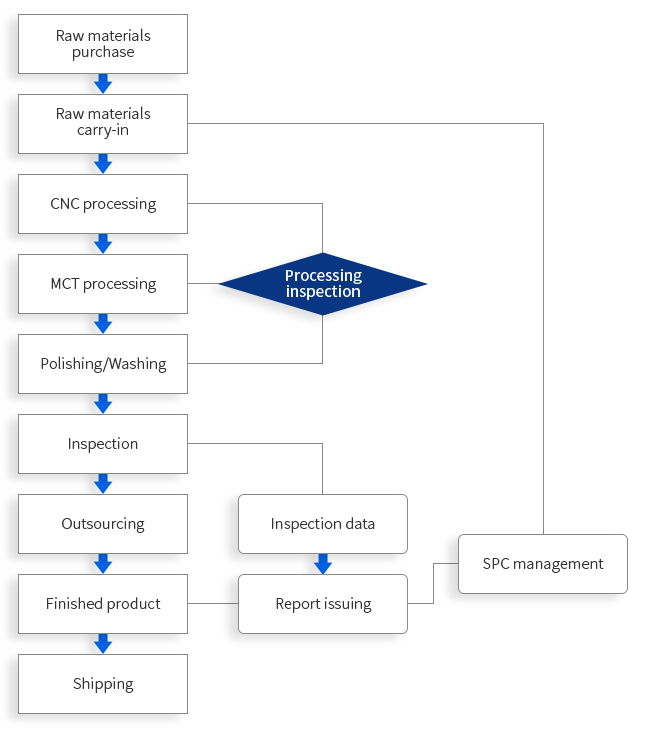

01. Systematic integrated quality system

Our quality system is operated systematically in association with computer-based system in all of the inspection processes from import inspection to shipping inspection. All of the data obtained in various kinds of inspection are registered in computer system and are monitored and analyzed in real time. Based on the registered data, We communicates with the production field in order to prevent quality problems. In addition, by analyzing trends, we make an effort to prevent problems from occurring again. We will do the best to prepare the future and grow further by performing the best quality management.

02. Optimized inspection & measuring equipment

Our inspection and measuring equipment is optimized to meet customers' quality needs. To measure the shower head that requires a precise size, we have contact & non-contact typed 3D measuring equipment. For more precise dimensions and measurement of all holes, we developed and apply relevant programs. In interaction with computer system, measured data are analyzed and managed in real time. Therefore, we conduct thorough analysis and management to prevent quality problems. To secure the accuracy and reliability of inspection data, we conduct daily inspection and regular inspection & calibration.

03. Customer satisfaction quality service

We puts communication in the top priority in order to meet a customer's quality needs. To achieve the quality level requested by customers, we established a systematic quality system and continue to monitor quality. By acquiring ISO9001:2015, ISO14001, and ISO45001, we laid the foundation for quality system. Setting up higher quality criteria than those of other processing firms, we make quality management strictly. By opening our mind, we will always make a lot of investment and effort to comply with the criteria requested by customers.

Our company established MES(Manufacturing Execution System), ERP(Enterprise resource planning), and Groupware to digitalize all processes. Production information is managed and shared in the computer-based system. Insung System will make reliable products and implement customer value quickly and accurately in the systematic digital environment.

Features of Computer System

-

Computer-based integrated management of all processes from material warehousing to product shipping

-

Minimum difference between production plan and production performance

-

Database of production and quality information

-

Automatic creation of reports and results

-

Standardization of production work

-

Management of product history

-

Security enhancement(user authentication, permission, and encryption)

-

Real-time data collection and sharing through system automation

Functions of Computer System

Flowchart of Computer System